The Steel Road Plates Ideas

Steel layers are give a good, short-lived option for covering hazardous openings on a building site. These durable, durable plates allow roadways to go back to service to make sure that building can proceed. Right here we discover the design information and ideal technique installment guidance. These plates can be made use of to ensure that roads can still be used whilst various other stages of work proceed.

They are often seen when excavations have actually started as a very early phase of building or fixing projects. These plates are developed to endure durable usage on hectic roads.

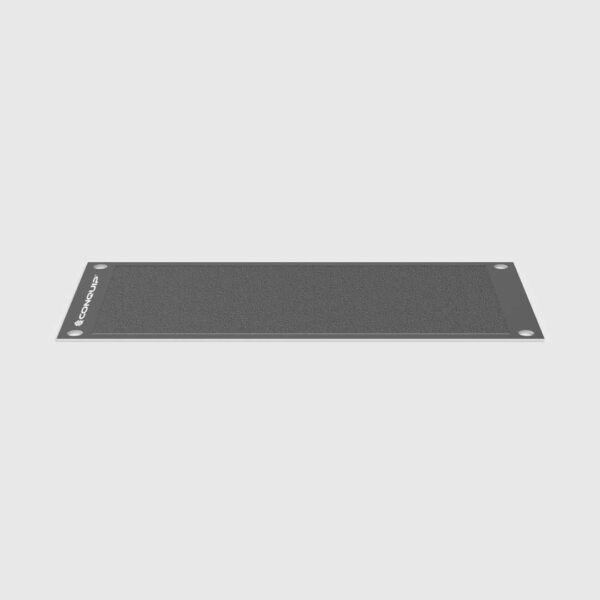

The weights start from about 300kg and basic roadway plates have a thickness of either inch or inch. The ability to be bolted to the road.

Indicators on Steel Road Plates You Should Know

Hinged versions for quick accessibility to the excavation or regular accessibility, e.g. driveways. Compound plates, which can accommodate numerous lengths of trench. Skid-resistance for boosted automobile, pedestrian and site employee security. Steel road plates can be installed relatively quickly, but they are hefty. Therefore, they ought to be installed utilizing a forklift or crane.

Look for variation by website traffic filling from the outset plates need to constantly stand up to displacement. Inspect that home plates do not present a threat to any kind of kind of road individual and can be made use of by all road individuals and lorry types, including pedestrians, bicyclists and motorcyclists. Develop a regular inspection and maintenance to make certain that performance stays safe and optimal.

Take care of home plates correctly whatsoever times. Mechanical training makes certain that the plates are installed precisely and securely. The right plates ought to appropriate for the preferred function Take into consideration suitable security areas, particularly when preparing installation. The weight of home plates can trigger turning in the construction area or across neighbouring carriageways/ footways.

If a ramp is developed by the road plates, then warning indicators for pedestrian and roadway individuals are called for. Constantly a conduct full site study, and take the specialist guidance of an architectural designer. The Department of Transport additionally supplies advice on mounting roadway plates, please click below. SafeSite Facilities (Steel road plates)' roadway plates are available for buy or hire anywhere in the UK.

About Steel Road Plates

In order to improve safety, there are a number of criteria and industry click here for more records guiding their use in construction job areas. Steel plates must be repaired in location to avoid movement.

Not known Facts About Steel Road Plates

Along with being securely touching the pavement, they ought to be either pinned, recessed into the pavement, or secured with asphalt wedges around the perimeter. Pinning into the pavement entails driving pins right into the sidewalks along the sides of the steel plates to avoid activity. Recessing includes eliminating the location where the steel plate will certainly be put.

This causes the steel plate being flush with the pavement. Furthermore, when multiple steel plates are utilized and butt as much as each Continue various other, they must be welded together at the longitudinal joints. Steel plates can be very slippery, particularly when they are damp, unless they have an anti-skid coating used.

Covering steel layers with a product that enhances rubbing assists motorcyclists and bicyclists keep control, especially in damp weather condition. Conditions which reduce sidewalk friction in job areas are of specific issue to motorcyclists and bikes. A typical danger in steel plate setups occurs when the user fails to build effectively tapered ramps from the roadway to the sides of the steel plate( s).

Not known Details About Steel Road Plates

It postures a substantial risk to motorcyclists and bicyclists that can easily lose control when they speak to the abrupt/steep tapered official site ramp and the steel plate. Appropriately tapered ramps permit individuals to safely go across over the steel plates.

Division of Transportation's Federal Freeway Administration (FHWA) calls for that transverse sidewalk joints, which cause a bump, must be tapered at 60 to 1 (5 feet horizontal for each 1 inch of vertical elevation difference). Select the correct dimension. Make sure adequate overlap. Typically, steel plates should prolong at least one foot beyond the pavement opening onto firm ground.

The Definitive Guide to Steel Road Plates

Welding is made use of when more than one steel plate is made use of and they butt up to each other. Plates have to be countersunk when needed due to uneven highways.

His background consists of the building and construction, inspection, learn more.

On the planet of civil design and construction, steel road plates are an ultimate device that holds tremendous value. These heavy-duty steel plates play a vital duty in enhancing building security, supplying temporary roads, and guaranteeing smooth procedures on numerous task sites. As a building devices supplier, their importance can not be overstated.